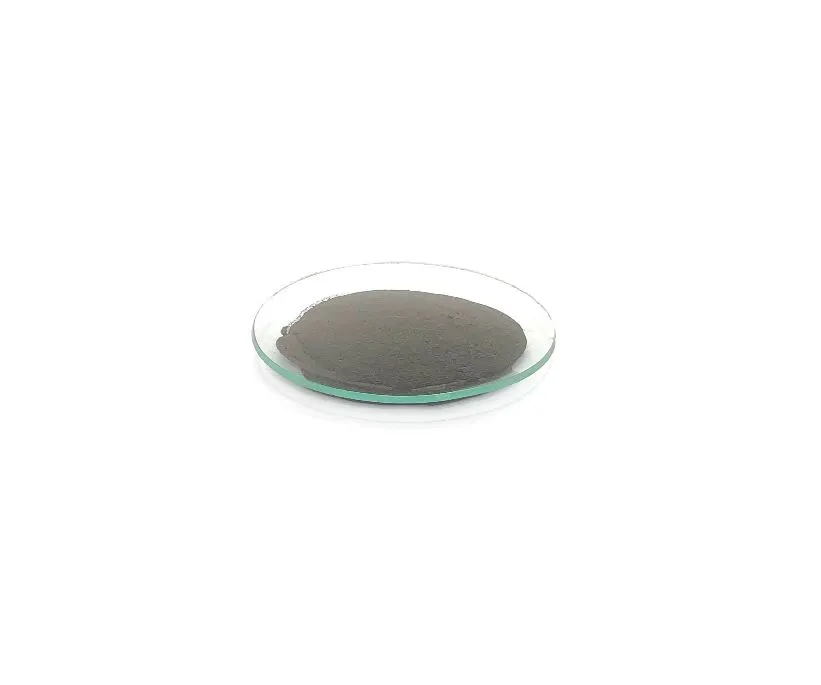

| TRADE NAME | PURITY | PARTICLE SIZE | A. D. (g/cm3) | T. D. (g/cm3) | OXYGEN | MORPHOLOGY |

|---|---|---|---|---|---|---|

| PM-200 | 99.5% MIN | <75 MICRONS | 3.2-3.6 | 4.4-4.6 | <0.5% | IRREGULAR |

| PM-300 | 99.5% MIN | <53 MICRONS | 3.0-3.4 | 4.0-4.2 | <0.5% | IRREGULAR |

| PM-400 | 99.5% MIN | <45 MICRONS | 2.6-3.0 | 3.5-3.7 | <0.5% | IRREGULAR |

| PM-500 | 99.5% MIN | <37 MICRONS | 2.2-2.6 | 2.9-3.1 | <0.5% | IRREGULAR |

| PM-10 | 99.5% MIN | <15 MICRONS | 1.6-2.0 | 2.4-2.8 | <0.5% | IRREGULAR |